Similar Posts

Principles for the Design and Making of Liturgical Furnishings

Aidan Hart

The newly installed choros of the Russian Orthodox Cathedral of the Dormition, London, designed by Aidan Hart.

Handing over from hand to machine

A tool in the hand of a craftsperson is an extension of their body, mind and soul. He or she feels the resistance of the stone or wood. Through the tool the material speaks back to them, and they adjust accordingly as they work. There is a dialogue conveyed through the tool.

An oak carving of the miracle of fishes, Iviron Monastery, Mount Athos, by Aidan Hart. The design was adapted as the work was carved.

This dialogue in turn informs the craftsperson’s design for the next project, because a good design uses the material’s limits as well as its strengths to advantage. For example, the beauty of the structural arch was born of the tensile weakness of stone, which works well under compression but badly under stress.

But what happens when we replace the tool with a machine or some form of technology? How does such mechanisation change the final work, for that intimate connection of the craftsperson and material has been lessened, or even severed? Does it affect not only the finish of the completed work, but also its design, for the design is invariably made with the machine in mind? Can the hand and heart keep master of the making, checking those short cuts that machinery and engineers like so much?

Some recent metalwork church commissions have forced me to deal with these issues in quite a practical way: a bronze choros chandelier; brass panelling; a silver episcopal staff.

Silver episcopal staff (detail), designed and carved by Aidan Hart and Martin Earle, cast and made by Hart Silversmiths (no relation!).

To discuss these issues is not an academic exercise, for while over the past decades we have seen a welcome revival of traditional principles of iconography, I and many others feel that Orthodox church furnishing production is still in a parlous state. The quality can often be high, but the design poor or distractingly ornate. Perhaps because more money is to be made from furnishings than from labour intensive iconography, the temptation within the church furnishing industry is to let profit rather than quality dominate.

So I thought I would share some of my conclusions, and see if others have their own reflections on the matter. The use of machines or computers to help design and make liturgical furnishings is surely not an inherently bad thing. The question is how to ensure that both design and execution are kept to the maximum quality so they best nurture worship. Some degree of machine production is usually needed to keep church furnishings affordable, but the challenge is to keep the machine a servant and ensure that design quality is high in the first place before a machine even touches the material.

Delegation

Mechanisation usually introduces a second matter that I will also discuss: the necessity to delegate. Whether we want something cast, machine cut, robot modelled or whatever, we usually need to involve a third party, be it a company or an individual. In doing this we inevitably relinquish some control. Such delegation is not in itself a bad thing. It can be seen as an extension of the medieval practice of the communal workshop. But as with mechanisation, how can the originator ensure that quality is retained?

Mechanisation and delegation are two very important and practical issues for communal worship because these processes impact the quality of the final furnishings, and these in turn impact, for better or for worse, the ambience created within the church interior. It is not just the quality of the chant, architecture and iconography that affect our liturgy, but also the quality of the furnishings, such the lighting fixtures, wooden seating, icon cases, stonework, even the colour of paint on the walls. These interior design elements cannot be an afterthought.

A service, showing how the furnishings occupy a large volume and therefore have a considerable impact on the liturgical atmosphere

Why use technology at all?

I am a Luddite by inclination. I think design is best pencilled by those whose hands are intimate with the material, whose minds know from experience the material’s weaknesses and strengths, and whose hearts respect it.

But sometimes limits of money and time demand that after designing one must then delegate at least part of the making to others and to technology. Handwork takes time and therefore money. Generally, machines are faster and therefore cheaper. And since budgets are usually limited, we need some form of assistance from machines.

And also, some materials just don’t like being worked entirely by hand, which most notably for churches is brass. If we are making a church chandelier for example, brass is an excellent material due to its resistance to corrosion and its golden colour. But the brass needs to be formed in some way. It can’t be carved out of a block, so will we cast it or cut it from plates? If the former, the prototype needs to be made, the object moulded and then cast, fettled and polished.

If cut from plates we cannot have bass relief, so how will this affect our design? All these processes require some form of technology and probably also delegation, but also skilful design to make the most of the material and the strengths and limitations of the chosen technology.

A radiator grill, cut by water jet. Note the absence of relief, appropriate for this function. Design by Aidan Hart.

But without the craftsperson’s marriage of mind, hand and matter, how does one ensure that the detail of works executed by a machine carry the designer’s original vision? Machines are great at repeating, but not at those perfect imperfections and variations that are part of the hand process.

These were the challenges that faced me when in 2016 All Saints Russian Orthodox Cathedral in London commissioned me to design and have made their articles in metal: a bronze choros (chandelier) for the sanctuary; eleven brass radiator grills; twenty-seven cast brass panels for the oak balustrades; and also, for good measure, a silver episcopal staff. The latter was to be given as a gift from the Archbishop of Sourozh and parishioners to the Patriarch of Moscow, who was due to come and bless the cathedral refurbishments.

The generosity of the chief donor meant that money was not a major concern. But with the date of the Patriarch’s visit set we had a deadline that was not so generous with time – three months to do everything.

Principles of mechanisation and delegation

These and other church furnishing commissions, such as a steel choros for a church in Belgium, have taught me some principles concerning mechanisation and delegation. Some of these principles I learned by obeying, and some I learned only in retrospect having failed to follow them.

- Delegate work but not responsibility. If someone commissions a work from us, then we are the ones ultimately responsible for its quality. We can’t pass the buck.

- Leave no ambiguity in the design. The makers and machine operators must know their mandate clearly.

- If something is to be machine produced, wherever possible still hand draw or model the prototype. It is from this process that the beautiful children of the heart, mind, and heart are generated. Computers might then be used to convert this design or prototype into a useable format, such as a CAD file, in order for the machine to reproduce it, but the original form itself remains hand wrought. If we relegate this first stage to computer modelling or to the engineer we are more likely to get a lifeless result. We have delegated responsibility and not just the work.

- Watch the detail. While a bad overall design will not be saved by fiddly attention to detail, sloppy detailing will sabotage a good overall design.

- When delegating our design’s execution to another party, even to a professional, clearly state the level of quality expected. I once commissioned a joiner to make two oak doors for a church, assuming they would use the best quality knotless oak as I had seen them use in most of their other work. However, the completed work had quite a few dead knots in it, and so it was hard work for me to convince them to do a complete remake at their expense because in the agreement I had not expressly stipulated the timber quality.

- Take nothing for granted. While not meddling in processes that we know less about than the experts, check the progress of production enough to ensure quality. For example, I didn’t check the wiring executed by the manufacturers of the cathedral choros before it was installed, thinking that surely they wouldn’t get it wrong. But they did, and the otherwise simple job of correcting it proved to be a complicated and expensive exercise because it had to be done in situ.

- Draw on the expertise of skilled colleagues, and be willing to improve our design accordingly. On the other hand, don’t succumb to pressure from the manufacturers to make a change that would compromise the beauty of the design simply because it is technically easier.

- Have a contract, and make sure that it covers the worse scenarios. It needs to make clear who is responsible for what so that if some element goes wrong it is clear whose job it is to remedy it.

- Keep clear in our mind the larger vision for the church’s liturgical life, and ensure that the details serve this vision. Technicians and their machines might want to compromise on details because these do not appear to them to be critical. But because the designer knows the larger picture and the work’s final role within the church temple, it is he or she who knows how important these details are for the enrichment of liturgical life.

- When a low budget requires a high degree of mechanisation in the production, still try to introduce as much handmade work as possible. Include this in a place where it draws attention away from the more mechanised areas. See for example the choros for a Belgium church, where I used hand forged steel links to offset the laser cut steel plate panels.

- Seek authenticity. Sometimes it is best to adapt the design to modern technology rather than use modern technology to ape old methods. With the Belgium choros, for example, we dropped the original idea of electrical candles to imitate wax candles in favour of concealed LED strip lighting around the base of the choros.

Choros in St Amandus Orthodox church, Kortrijk, Belgium, made of laser cut sheet steel, powder coated. Design by Aidan Hart.

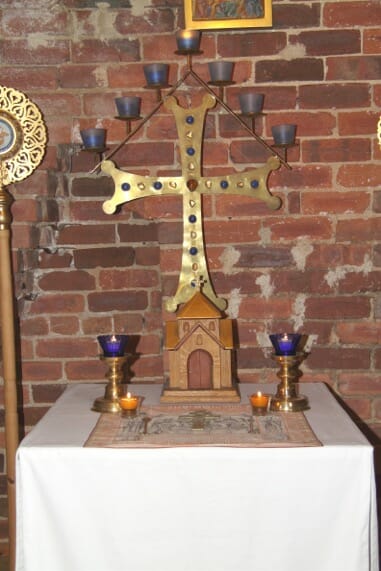

A bronze choros

Archbishop Elisey asked me to come up with some lighting solutions for his cathedral in London. Part of the proposed solution was to design and have made a brass choros for the sanctuary, with the possibility of making similar ones elsewhere in the nave. After many technical challenges and with the help of an experienced manufacturer it was finally made and installed in time for the Patriarch of Moscow’s visit on October 16th, 2016.

It is cast in silicon bronze using the lost wax process. Due to the time pressure, unfortunately everything but my original drawings had to be delegated to the company and made largely by machine. Based on my pencil plans they prepared CAD files (Computer Aided Design) and from these made the prototype forms by CNC, a sort of computer operated robot that is essentially a glorified router. Silicon rubber moulds were made of these forms, and then wax positives cast. The bronzes were then cast using the lost wax process. Quite a process!

Like those made by Andrew Gould and myself in the past, the inspiration for the choros’ design was the medieval Byzantine type rather than the more Baroque styled ones that most commercial companies produce today. In the past I, like Andrew, had made steel ones, using laser-cutting techniques to cut the shapes out of sheet metal. But in this commission the budget permitted us to cast rather than cut the elements. This allowed relief work, something not possible with cut sheet metal.

A major challenge was to conceal the electric wiring as much as possible. To this end the corner crosses were cast with a vertical channel through which the wires are fed. The manufacturing company came up with an ingenious method to do this, so I learned Point Seven.

A corner cross of the London cathedral choros, showing how the wires are concealed inside a vertical channel.

The main function of this particular choros was to cast light downwards, towards the holy table, so I omitted the candles usually found atop a choros and used hanging glass bowls instead, hand blown by a local craftswoman. These are lightly tinted white so that the light bulbs are not visible. To hold the low energy bulbs that throw a light downwards I devised a cradle system that sits on the lip of the bowls.

The vine panels were designed to harmonize with existing wood and stone carving in the church. Although their outlines were made according to my pencil design, due to time pressures the prototype for the lost wax casting process was made by computer modelling. Although everyone seems pleased with the result, I think that in retrospect the panels would have been even better if the prototype had been hand carved. There are all sorts of important details that are worked out in the process of hand carving, and this is missed in computer modelling. For example, I would have probably faceted the vines and leaves to catch the light, whereas the computer modelling favoured rounded cross sections.

Balustrade Panels

The cathedral is essentially a basilica, with columns of cast iron skilfully marbled to imitate porphyry. But it also has galleries over the aisles, whose oak balustrades had got rather dark and similar in tone to the columns. This meant that the strong horizontal line of the balustrades compromised the vertical elegance of the columns. The balustrades needed to be made more distinct from the columns.

The solution was to strip the oak back to a lighter tone and replace the existing plywood panels with brass filigree. The new panels were based on the choros design. They were cast locally using the sand cast technique and then skilfully polished.

Sand casting is a much cheaper process than lost wax casting, but tends to be a bit more crude, can’t handle undercuts very well, and needs more cleaning up (a process called fettling). So in deciding which process to use one has to balance the casting costs with the detail required, and also the time needed to fettle and polish the castings.

Even though the final works are quite successful, I would have preferred more time to fine tune details of the prototype before the casting began. I had delegated the making of this model to a third party, but the pressure of the deadline did not allow me time for a visit to him part way through the process. Although I had stipulated that I wanted the leaves and branches to be faceted rather than rounded, and had emailed an image of an example, I didn’t ensure that this detailing was followed through. Principles 1, 2 and 4!

Radiator grills

As part of the refurbishment the aisle heating radiators of the cathedral had been encased in panelled oak. I was asked to design and make brass grills for the tops. In a rather broad way I based these on a vine scroll to harmonize with the carvings in the icon screen and wooden icon cases, but used as inspiration the fine decorative borders found in Russian and Byzantine illuminated manuscripts.

But there were practical requirements as well as aesthetic. The openings had to be small enough so that articles couldn’t fall through, yet large and numerous enough to allow the hot air to transmit freely.

Water jet technology was used to cut the shapes out of sheet brass. In this process a high pressure jet of water carries fine abrasive particles that cut cleanly through the metal. It is slower and more expensive than laser cutting, but produces a much cleaner edge.

The cutting company required the design to be presented in what is called a DXF polyline file format, so my colleague and assistant Martin Earle performed his computer wizardry on my pencil drawings to produce these files. This was an interesting exercise, where the broad design was produced in pencil but then refined by both of us on the computer. The software permitted curves and thickness to be fine-tuned much more cleanly and quickly than with pencil, and for sections to be copied, mirror imaged, and grafted in seconds. It saved a lot of time without loss of quality.

Silver patriarchal staff

Archbishop Elisey also commissioned a silver episcopal staff for the cathedral to give Patriarch Kirill at his visit. His Eminence wanted the staff to represent the pre-schism Orthodox heritage of the United Kingdom, so we decided to include designs inspired by the Celtic, Anglo Saxon, Roman and Romanesque periods.

I first designed it in pencil, then I carved the prototype Tau head and Martin and I the spheres. We used a dense foam material. This is a modern material, which though rather dead and characterless in itself is nevertheless very useful for carving forms that will be cast. It is strong and stable and comes in varying degrees of density and hardness. Its main advantage in this case was that it is without grain, which means that it can be cut in any direction.

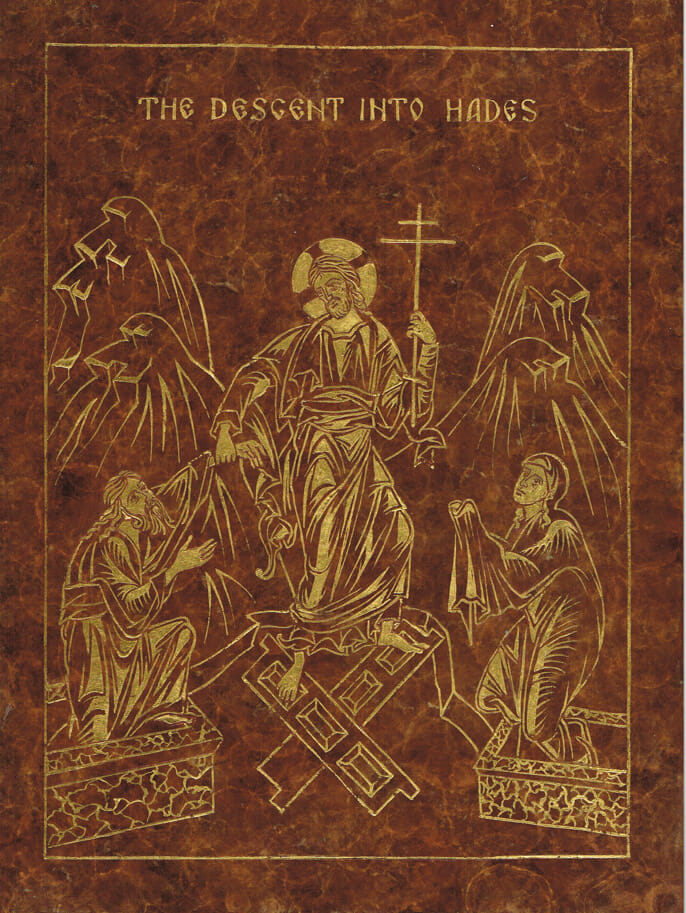

The inspiration for the Tau head was an ivory carving dating from around 1000AD, from Koeln, Germany The design combines the Crucifixion on one side with the Resurrection on the other. Adam and Eve on the Resurrection side are mirrored by The Mother of God and St John on the Crucifixion side.

22. The inspiration for the head of the episcopal staff, an ivory Tau crozier from Koeln, Germany, about 1000AD.

The designs on the spheres that cover the threaded joints are inspired by early Roman, Celtic and Saxon works.

I then commissioned a small silversmith studio to cast the pieces and assemble the parts. The spheres and head were cast into solid silver using the lost wax process. The spiral stems were brass bought off the shelf, and the silversmiths turned the foot in brass. They manufactured the threaded bars which fit within the spheres to allow the staff to be separated into four sections. Once everything was made, the whole work was silver plated – not necessary of course for the solid silver parts, but for the brass components.

The cut-outs for the foam cushions in the carry case were designed on paper, made into a CAD computer file, then cut by robot. This saved time and therefore money, and was guaranteed to cut out the spaces accurately so the staff sections snuggled in safely.

All the processes described above raise the question of the relative merits of computer vs. pencil when creating design, of hand vs. machine fashioning, and of synthetic materials vs. natural, subjects to which we shall now turn.

Pencil or mouse?

Personally I find it essential to design by hand rather than by computer. The computer can be useful for fine-tuning some designs. Once scanned, you can shift already drawn elements into different positions and edit details. And in any event, a machine making process often requires a computer generated format to read – CNC requires a CAD to use technical jargon. And sometimes it is helpful to have the stimulation and knowledge that the web offers so abundantly, if not in depth at least in extent. In a few seconds we can access a hundred images of liturgical arts for inspiration. Software can also take the drudgery out of some processes, freeing time for more creative work.

Nevertheless, the computer is to my mind a clumsy tool for originating good design. There is a suppleness of creativity when hand and mind work together to produce drawings, paintings or maquettes. The architect Frank Gehry often produces his first designs with bits of twisted cardboard. Only then does his team apply the force of aviation computer technology to realize his cardboard dreams.

There is also something potent about many different ideas being channelled into one fine point – the brush, pencil or pen. Computer software offers a vast array of possibilities, but in the early stages of design these can too easily dissipate and distract the mind. Software and the internet offer the world at our fingertips. The computer screen entices us to fan out, into an ecstasy of endless possibilities, whereas the brush or pen gathers the multitude into a point.

For the liturgical artist the environment for the design process should engender an atmosphere of quiet, prayer, contemplation, focus. Liturgical design is an act of instasy not ecstasy. Manual design – be it by pencil, brush or model – keeps this process more interior than computer drawing, which tends to exteriorize the activity. To make liturgical art one must try to have the music of heaven within oneself, listen to it, and design only what harmonizes with that music. In this sense liturgical art is as much an act of prayer as an artistic act, an act of communion as an act of creation.

Hand versus machine

Archimandrite Vasileios, the retired abbot of Iviron Monastery, Athos, often reminded me that there exists an imperfect perfection and a perfect imperfection. Machines tend towards the imperfect perfection, and handwork towards the perfect imperfection. Take for example a brass seven branched lamp that I made for a chapel. It would have been much easier to use machine rounded stones and manufactured settings. But study of medieval set stones convinced me that their charm lay in their irregularity. So I chose irregular semi precious stones, and hand made each setting in silver.

I think that if finances were no impediment, everyone would prefer hand crafted over machine made. However, finances are often a large factor, and sometimes we therefore need to look to machines to help out. From my experience there are a number of things that can help stop machine work compromise aesthetic quality:

- Wherever possible, hand craft the prototype. This can then be scanned. Modern technology is reasonably good at making accurate copies.

- If for some reason some or all of the design is to be made directly on the computer (for example, for cutting designs into stone for an icon screen), refer closely to masterpieces for detailing. For example, how deeply do these masterpieces cut into the stone? I have seen too many robot cut reliefs that are far too shallow. This is not the fault of the machine but of the designer

- Ask if a machine will do the job better or as well as yourself. If it can, and it is cheaper, then use it. A simple example is the foam cutting for the patriarchal staff case mentioned above, or CNC roughing out as described below.

- A machine can sometimes be used to do the roughing out, and then the artistic modelling completed by hand. As long as the artist has created the maquette, the roughing out of the final work is sheer labour, and can be achieved as well, if not better, by machine. And it releases the craftsperson to spend more time on the artistic fashioning. I did this with a seven ton block of stone that I was to carve into a statue for Lincoln cathedral. I hand modelled in clay a half size maquette, which I then cast into plaster. I worked further on the plaster and then this was scanned and turned into a CAD file. This in turn was given to a company who used a CNC robot to rough out the stone block in full scale to within 25mm (one inch) of the final surface. From there my assistant and I hand carved everything by hammer and chisel. The traditional point, claw and flat chisels have not been bettered for centuries. We did use a pneumatic chisel for one or two deep sections, but the horrible noise this machine makes destroys the meditative and thoughtful atmosphere one needs to make the multitude of decisions required in the process of carving. And it places the carver at one further remove from intimacy with the stone. So we kept its use to an absolute minimum and cherished the use of our hand chisels and mallets.

- Don’t presume that machines have to be monotonous, repeating the same design. I have seen exactly the same section of biomorphic design unnecessarily repeated the full length of a robot cut iconostasis epistyle. It would have been little more expensive to programme the robot to vary the details a little.

- Look at combining machine and handwork in the same piece. The machining helps keep down the price, while the handcrafted parts – if in visible places – can give the finished work much of the grace and tactility of a fully handmade piece. Most of the moulding in the illustrated icon screen was cut by hand, using either a scratch stock or a moulding plane. Images 30, 31 The advantage of these tools is that, compared to an electrical router or a spindle moulder, they create a slight undulation on the surface that begs one to stroke it. Also, scratch moulding burnishes the surface, which makes it even more tactile and plays with the light in a way that router cutting does not achieve. I also finished most of the flat planes with a cabinet scraper, which again burnishes the surface and produces a superior finish to abrasive papers. The rest of the work was done using modern machinery – bench saws, planers and thicknessers and so on.

Natural materials versus synthetic

Following the adage of a perfect imperfection, natural materials win hands down over synthetic materials. Their natural variation gives them life. I remember Father Paisius (now Saint Paisius) of the Holy Mountain telling me that when God made lights for the night He spaced the stars irregularly, varying their colour and size. This is gentle to the eyes. But when modern man makes lights for the night he places streetlights exactly the same distance apart, at the same height, and makes them the same intensity. This is monotonous and therefore tiring.

This article is primarily about church furnishings, and metal objects in particular. Metals are very practical because most are durable and strong, which is why brass and silver are often used for things such as church lighting, covers and receptacles. Even though metals need to be extracted from their ores by technology, they are nevertheless “natural”; they are elements that exist in nature and are not synthesized by us. However, by their nature they are very uniform and therefore tend towards monotony if not handled properly.

Metal’s uniformity helps explain why, for millennia, crafts people have tended to embellish their metal objects. They carve or cast forms into them, patina them with oxides, undulate their surfaces to play with light reflections, create interest by contrasting matt backgrounds with polished foregrounds. So we need to know the strengths and weaknesses, the predilections of our materials.

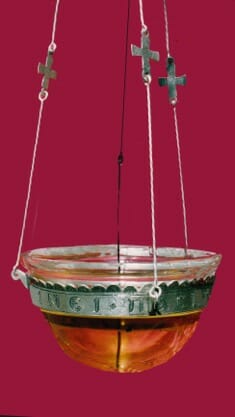

32. Silver lamp, Iviron, Mount Athos, showing carved lettering on the solid silver band. By Aidan Hart.

34. Plaque, gold on patinated copper, for doors in St Seraphim Orthodox Church, Santa Rosa, USA. By Aidan Hart.

Apex cross, showing the play of light on the rounded surface. The Russian Orthodox Cathedral of the Dormition, London. By Aidan Hart.

This process can be likened to the second stage of the spiritual life, called natural theology or illumination. In this stage we are called to discern the logos or divine word of each created thing. This is its essential name. We are called to bring out all the material’s potential, neither to leave it in its raw semi-articulate state, nor to force it to do something against its nature.

Conclusion

Undoubtedly icons, frescoes, and wall paintings need to be hand made. But things are more complex when we enter the world of church furnishing since some degree of machine work is usually required to keep things affordable. Nevertheless, I think that if both commissioner and craftsperson want the maximum quality within the budget, then with common sense and by following the principles described above they can produce work that is truly liturgical. It will resonate with the heavenly worship of which worship on earth is a participant.

Thank you, Aidan, for these excellent thoughts. As someone in much the same boat as you (with regards to designing and making liturgical furnishings), I have experienced many of the same opportunities and pitfalls.

We are designers and artists at heart, and our strength lies in conceiving of things and drawing them. Figuring out how to have them made efficiently takes so much time. There is a certain pleasure in this – in the engineer-mentality of coordinating a complex manufacturing operation. But in my experience, as soon as the process starts to become really efficient, it becomes so boring that it looses my interest. I just want to go back to making things with my own hands.

I think that attempts to make artists and manufacturing engineers collaborate has always been a stressful marriage. There were famous efforts in the late-19th and early-20th centuries, like Morris & Co., Liberty of London, Stickley Furniture, etc. These operations produced wonderful things, but they were short lived and burnt out their artists.

Our clients’ desire to have customized projects of handmade quality at machine-made prices forces us to attempt a difficult collaboration, somewhat unnatural for us artists. I sincerely wonder whether it is better for us to embrace it, so we can produce far more work for the church, or whether we should resist it, and make only small things with great love. I suppose there needs to be a balance of both.

I am enjoying this journal. Excellent work!

Thank you, Andrew, for your response. I suppose all of us would prefer 100% handmade work, so the aim of my article was to mull over the principles to have in mind when the budget requires some mechanisation. Each case is different, so I suppose the final guideline is to make the best possible work within budgetary restraints. In fact, often such restraints can lead to work with a higher spiritual quality. I made the silver lamp illustrated above (photo 32) with a masonry nail, tin snips, hand drill and hammer, and it is among my the lamps I am most pleased with. In fact, when the curator of the NY Metropolitan Museum visited Iviron looking for pieces to show in a large Byzantine exhibition, he initially mistook it for an early Byzantine lamp!

That’s an amazing story.

Dear Aidan,

Thank you very much for such a text, – expressive and full of insights! I would be honored if you allow me to add a little note:

Tools are “extensions of our hands” in one more very delicate sense.

Technically from what we see in artworks of our predecessors, they calculated the amount of their efforts for every job very meticulously (grudgingly/skimpily?)… Of course, their physical interaction with materials was much harder, their clients were not so requiring et cetera et cetera, – there can be a great variety of explanations, but I would suggest a theological one.

From what we can read of that time, the craftsmen of pre-industrial time considered their work to be kind of a dialog speech.

Their part of the “talk” was applying their best the skills to materials, created by God. Other part was in the materials themselves, more precisely – hearing the God’s “word”, to be revealed through the materials.

So, I would even dare to say that these craftsmen constantly offered the first place to God, letting Him reveal Himself through creation. These people were “saying” with their respectful hands as little as possible, when in their work they were consciously rather showing essential qualities of the materials than demonstrating their possibly great skills.

In our days with electricity and other contemporary possibilities we feel much more skilled then our colleagues from the past. Current marketing situation and these new abilities tempt us to get “nicer” results, which consequently tempt us to “say” more with our skills, giving God less space in this dialogue. The same – applying of machinery and tools may be measured and applied in such an amount, which will be in first place praising God, rather than showing in this case achievements of modern technologies.